.jpg)

OTTOMAN FACTORIES: A HISTORICAL REEVALUATION OF INDUSTRIAL ACHIEVEMENTS

It has been a common practice to attribute Turkey's backwardness to Ottoman economic policies. According to this view, the Ottoman Empire granted privileges to major powers through recent trade agreements, and the resulting free trade environment undermined local industries left unprotected. The Ottoman Empire is portrayed as a backward country dependent on external sources, unable even to manufacture a "sewing pin." [Even today, sewing pins are imported.]

Yes, politics and economics are inseparable, but considering the Ottoman Empire's military and political decline in the last century as a complete acceptance in economics, even in science and art, is a significant mistake. Numerous academic works, theses, and articles have been written on this subject in recent times, but for some reason, they are often overlooked.

Industrialization Behind Closed Doors

The conquest of new continents, overseas trade, the flow of gold and silver to the continent, the price revolution, industrialization, production of goods for the market, consolidation of land, increased efficiency in agricultural production, the emergence of surplus labor, rapid population growth, supply and demand for non-agricultural labor, transition to a unified monetary system, banking, circulation of banknotes, transformation of commercial capital into industrial capital—all these factors brought about favorable conditions for industry in Western Europe. At the end of the 18th century, the Industrial Revolution, starting with England, gave birth to capitalism.

Industrialization cannot be achieved without a policy of free trade, and a static economy with high tariffs. Neither Colbertism in France nor the economic currents known as Cameralism in Germany led to industrialization. Economic development cannot occur without external dependence. Industrialization behind closed doors is a utopia. Protectionism directs development potential but cannot achieve it on its own. Industrialization is the result of three things: trade, agriculture, and population revolution.

Third Option

The Ottoman State, which was dominated by a protectionist economic system and primarily aimed to feed its own society, had a virtuous mission that was quite different from Western Europe. Here, a small-scale industrial sector operating on classical methods was active.

Ottoman administrators were well aware of what was happening in Europe. They had to choose between shutting their ears and doors to the modern world, living in a medieval manner, or risking colonialization by doing nothing. Despite paying a heavy price, they chose a third option.

Following economic rationality, they sought to create these favorable conditions starting from Sultan Mahmud II. They opened the closed and protectionist Ottoman economy, which relied on its own resources, to the international market. The craftsmen who could adapt to the developments and new techniques continued their existence, while those who could not adapt ceased their activities.

Ottoman Manchester

In the early 18th century, often belittled as the Tulip Period, the Ottomans embarked on an industrial revolution. Factories for paper, tiles, porcelain, and weaving were established. This period, heralding Ottoman industrialization, came to an end in 1730 as a result of a coup.

Not long after, Sultan Mustafa III, Sultan Abdulhamid I, and Sultan Selim III revisited the issue of industrialization. Engineering schools were established, laying the foundation for what is now Istanbul Technical University. During the Nizam-i Cedid (New Order) period, factories were established, including the Beykoz paper mill (1804), Beykoz leather and shoe factory (1812), Paşabahçe spirit (1822), Eyup yarn (1827), and Islimiye cotton (1830) factories.

The Ottoman elites aimed to transform the area from Yedikule to Zeytinburnu, Bakırköy, Yeşilköy, and Küçükçekmece into an industrial park, almost like establishing a city similar to Manchester, Leeds, Birmingham. Despite the negative effects of the Baltalimanı Trade Agreement signed with England to form an alliance against Russia and France, which reduced the competitiveness of local goods against imported goods, it ensured the opening of the Ottoman economy to foreign trade. In the long run, the volume of foreign trade grew.

.jpg)

Debunked Paradigm

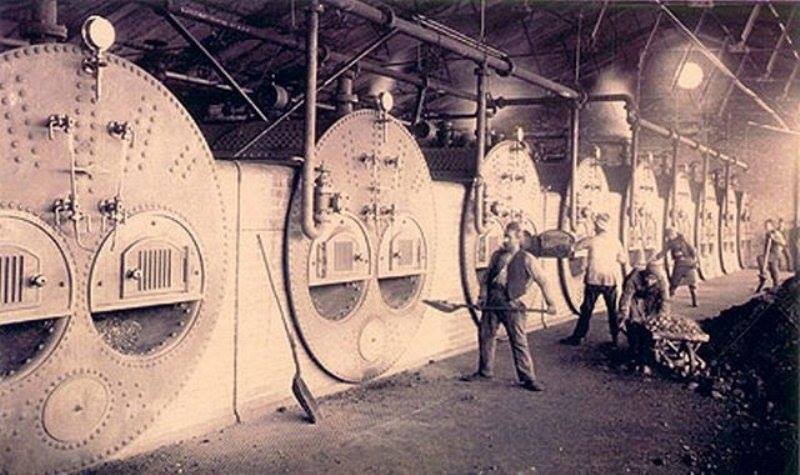

Edward Clark's interesting article "The Ottoman Industrial Revolution," published in 1974, debunks the paradigm that suggests the Ottoman Empire failed to catch up with the industrial revolution. In fact, archival documents indicate that the Ottoman State had a significant industrial program that was being attempted and should not be underestimated.

During this period, especially from the resolution of the Egyptian issue to the Crimean War, a serious industrialization movement led by both the state and the private sector was observed. Textile factories, particularly, stood out, along with food, oil, soap, cement, and brick factories.

One-fourth of the budget revenues were allocated to industrial investments during this period. The Commission for the Improvement of Industry was established, providing incentives. Local trade fairs were organized starting from 1863, and participation in international trade fairs increased. Industrial schools were established from 1864 onwards. Engineers, craftsmen, and technicians were brought in from abroad along with tools and equipment.

Various imperial factories and military production facilities were established in fields ranging from textiles to foundries. These belonged to the Ministries of War, Navy, Arsenal, or the Imperial Treasury. During this period, industry was more focused on assembly. Industrialization was guided by the needs of the military and the palace.

Transformed Appearance

During this period, significant expenditures were made for industry, and funds were allocated in the treasury. All these factories transitioned to the Republican era. Industrialization transformed the appearance of cities. In his travelogue, Banbury mentions that in 1876, Samsun was a small fishing town with a few thousand inhabitants, whereas Erzincan had become a prosperous city with 30,000 residents due to its textile, leather, and footwear factories.

While industrialization led to budget deficits, financial difficulties, and external borrowing, it also resulted in the formation of a working class. Despite facing a shortage of skilled workers, it contributed to the accumulation of experience and knowledge for the future. State-owned factories, aiming to meet the needs without pursuing profit, produced goods at high costs and eventually became sluggish, posing a burden over time by remaining indifferent to market prices.

The government supported private-sector factories as a result of which significant enterprises such as Feshane, İzmit cotton, Veliefendi printing, Hereke fabric, and Bursa silk factories were established. Important establishments like the olive oil factory in Msallata (Libya), Söke licorice honey (1849), Beirut silk (1851), Bitola barley broth (1862), Edirne silk (1864) factories are examples of this. The products of the Rize fabric factory won first place at the 1855 Paris World Fair.

Smoking Factory Chimneys

Some of the important large factories established over a century include:

Ceramics and pottery: Beykoz Ceramics Factory (1845), Yıldız Ceramics Imperial Factory (1890-92),

Electricity: Dolmabahçe Gas Plant (1853), Beylerbeyi Palace Gas Plant (1862), Yedikule Gas Plant (1880), Kadıköy Hasanpaşa Gas Plant (1891), Silahtarağa Electric Power Plant (1910-13), Üsküdar Electric Factory (1911).

Leather and footwear: Ottoman İttihat Saddlery Company (1913), Beykoz Shoe Factory (1884).

Textile and clothing: Feshane-i Amire (1839), İslimye Şayak Factory (1840), Hereke Imperial Factory (1843-45), İzmit Cotton (Woolen Fabric) Factory (1844), Hereke Cotton Factory (1845), Bursa Silk Factory (1846), İzmir Muslin Dyeing and Printing Factory (1847), Bakırköy Fabric Factory (1850), İzmir Fabric Factory - Printing House (1861), Kula Textiles (1866), Kırkağaç Cotton Spinning Factory (1876), İzmit Silk Factory (1880), Adana National Textile Factory (1907).

Chemistry: İzmir Oil Factory (1850), Beykoz Spermaceti (Candle Wax) Factory (1863), Second İzmir Oil Factory (1870), Tannin (Acid) Factory (1891), Küçükçekmece-Ottoman Match Factories (1898), Galata Yüksek Kaldırım Battery Factory (1917).

Machinery and metal: Zeytinburnu Iron Factory (1843), Yedikule Railway Factory (1843), Eskişehir Railroad Construction Factory (1894), Şakir Zümre Stove Factory (1918), Zeytinburnu Rifle and Cartridge Factory (1902), Zeytinburnu Acid and Ether Factory (1902), Zeytinburnu Chemistry Factory (1902).

Military: İstinye Shipyard (1856), Imperial Arsenal for War Supplies Manufacturing (1868), Kayseri Gunpowder Mill (1891-92), Konya Gunpowder Mill (1896).

Food: Selimiye Pasta Factory (1830).

Tobacco: Cibali Tobacco Factory (1884).

The Ottoman industrialization, which began in the early 18th century and turned into a vigorous activity by the end of the century, did not achieve success comparable to England, France, or Germany. There are several reasons for this. The Ottoman economy lacked the dynamics present in Western European industrialization. There were four main reasons for this: land, population, geography, and mentality.

Large Land, Small Population!

After the Tanzimat era, the status of state-owned land, which the people cultivated through leasing, almost took on the form of private ownership. However, with the increasing number of landowners, the land was divided and reduced in size. Fewer people had to work in agriculture so that increased productivity could feed the cities, and surplus labor could be shifted to industry. Indeed, the French revolutionaries had delayed industrialization in order to protect the peasants.

Secondly, the Ottoman population was very low, a problem that could only be overcome after 1950. In contrast, the European population, which was 100 million in the 1700s, had increased to 450 million by the early 1900s. Deaths due to factors such as famine, infectious diseases, and wars had decreased, and the development of medical techniques contributed to this. At this time, the Ottoman population consisted of around 20 million people, living in territories that were much larger than Europe.

Thirdly, the unfavorable geography with rugged, barren, and impassable mountains, along with a lack of rivers suitable for transportation, worked against the Ottomans. Coastal areas and places accessible by caravan routes could be opened to the market, while the interior regions had to wait for the arrival of railways. The concentration of industrialization in Istanbul and its hinterland, where transportation was easier, resulted in the deprivation of other regions. As a result, the production of industrial crops was also delayed.

Being a Laborer?

Finally, in Ottoman society where demand for goods and services was low, technical labor did not develop. In a conservative society resistant to change, craftsmanship, free from concerns such as time and profit, was preferred over industry, which required precision and coordination.

The patriarchal structure has prevented the people from becoming "laborers." Since there was no land slavery and property loss, the proletariat did not emerge. Working for wages with manual labor was somewhat looked down upon; securing a job within the state was the dream of every young person. This is still an unresolved issue of mentality.

There was no real financial source for these major investments. Machinery and equipment were imported from abroad. Technicians, craftsmen, and even workers were initially brought in from abroad. The enterprises were not managed very well. The state was the biggest buyer of industrial products.

Is Industry a Waste?

In the 19th century, there were many elites who considered industry unnecessary or even wasteful, emphasizing the importance of agriculture. Even Cavit Bey, the liberal finance minister of the Young Turks, shared this view. The only exception was Ahmed Midhat Efendi, who fervently defended industrialization. Sultan Abdulhamid II, especially known for his unparalleled efforts in education and development, attached particular importance to industrialization.

Sultan Abdulhamid II, from his days as a prince, had been involved in trade, agriculture, and industry as an entrepreneur. He established a vast economic empire, resembling a modern conglomerate, with his personal wealth, including the Imperial Treasury, farms, mining operations, and factories.

He was the one who introduced the two-tiered silver industrial medal to encourage entrepreneurs. Numerous factories established or active during this period, as well as examples of art schools, can be found in the Yıldız albums.

Factories of the Sultan Abdulhamid II Era

As far as we can glean from the yearbooks, the number of factories built or renovated during the reign of Sultan Abdulhamid II is as follows:

17 carpet factories (Bandırma, Hereke, Oriental Carpets, İzmir, Karacabey, Gördes, Uşak, Isparta, Kula, Eşme, Milas, Kayseri, Sivas, Niğde, Merzifon, Maraş);

15 weaving factories (Eyüp Defterdar Fez and Woolen Fabric Factory, Fez and Military Clothing Factory, Darülaceze Hamidiye Fez Factory, Bakırköy Fez Factory, Bursa silk weaving factory, İzmit Cotton Fabric and Cotton Yarn factory, Edirne, Mosul, Aleppo, Thessaloniki, İzmir, Adana, Rize, Beirut, Tripoli weaving factories);

3 yarn factories (Bursa, Istanbul Yedikule, Tarsus);

2 paper mills (Beykoz, Beirut);

3 porcelain glass factories (Yıldız Paşabahçe, Çubuklu); 2 match factories (Küçükçekmece, Beirut);

5 leather and footwear factories (Beykoz, Erzincan, Diyarbekir, Mosul, Beirut);

2 brick tile factories (Istanbul Kireçburnu, Thessaloniki, Beirut);

5 iron factories (4 Bursa, 1 Bursa);

2 canned food factories (Istanbul, Thessaloniki);

2 alcohol factories (Izmir Tepecik, Gallows);

1 gunpowder mill (Konya);

2 gasworks (Istanbul Yedikule, Izmir);

1 diamond processing factory (Bursa);

40 flour and ice factories (Bursa, İzmir, Beirut, Thessaloniki, Kavala, Lüleburgaz, Adana, İzmir, Edirne, Hudaydah, Baghdad, Basra, Aleppo);

2 spermaceti candle factories (Istanbul, Beirut);

1 pasta factory (Beirut);

1 oil factory (Bursa);

1 cannon and howitzer factory (Istanbul Tophane);

1 bullet cap factory (Karaağaç);

1 artillery material factory (Imperial Arsenal);

1 rifle spare parts factory (Baghdad);

1 bullet cartridge factory (Istanbul Zeytinburnu);

2 gunpowder mills (Istanbul, Ankara).

In addition, hundreds of weaving, watch, carpentry and furniture, iron foundry, photography, paint, soap, sesame oil, cotton gin, lumber, horseshoe manufacturing workshops were opened.

Wealth, Power and Industry

Between 1883 and 1913, a total of 46 industrial establishments were established with national capital, and 39 with foreign capital. Despite everything, after the Constitutional Monarchy, the vigorous industrialization policy of the Sultan Abdulhamid II period was followed. The industrial anthem that concludes with "Demektir ki varlık sanayi ile kâim/Demektir ki kudret sanayi ile bâki" (This means that existence is sustained by industry/This means that power is everlasting with industry) by Süleymanpaşazade Sami Bey echoes this excitement.

In 1913, the Industrial Encouragement Law was enacted, providing exemptions for factories. Industrial chambers were established, industrial magazines were published, and industrial schools were founded. The number of factories increased, with significant development in the food industry.

Industrial statistics were compiled. According to this, in 1915, there were 283 factories throughout the country; in Istanbul (149), Izmir (61), and other cities (73). One-fifth of these were state-owned. One-fifth of those owned by individuals belonged to Muslims. Small workshops and ateliers are not included in these figures. These factories employed 15,000 workers and they had the right to strike.

.jpg)

The Legacy Left to the Republic

Those who scoff at the industrial legacy of the Empire claim that 45 factories were established in the first 15 years of the Republic. The Republic administration, declaring its commitment to a liberal economy during the 1923 Izmit Economic Congress organized during the Lausanne Conference, managed to appease the objections of major powers. However, later on, it shifted towards a strong statism.

In an economy closed to the outside, under a tight statist, oppressive system where the people lived in misery, with no freedom or democracy, and where all resources were in the hands of a single party and its team, what purpose did 45 factories serve?

Since most of the established factories did not belong to the public/private sector, they served no purpose other than strengthening the totalitarian regime; however, the crisis it caused accelerated the transition to democracy.

A large part of these 45 factories was inherited from the empire and underwent revision. Some were warehouses, shipyards, dams, military repair workshops, or mines. In many cases, only the foundations were laid.

References:

1. Abdullah Martal, Osmanlı Sanayi Devrimi Üzerine Düşünceler (Thoughts on the Ottoman Industrial Revolution), 1998.

2. Donald Quataert, Manufacturing and Technology Transfer in the Ottoman Empire (1800-1914), 1992.

3. Donald Quataert, Manufacturing in the Ottoman Empire and Turkey (1500-1950), 1994.

4. Donald Quataert, Ottoman Manufacturing Sector in the Age of Industrial Revolution, 1999.

5. Edward C. Clark, Ottoman Industrial Revolution, 1974.

6. Ekrem Erdem, Sanayi Devriminin Ardından Osmanlı Sanayileşme Hamleleri: Sanayi Politikalarının Dinamikleri Ve Zaafiyetleri (Ottoman Industrialization Efforts After the Industrial Revolution: Dynamics and Weaknesses of Industrial Policies), 2016.

7. Haydar Kazgan, Osmanlı’dan Cumhuriyet’e Şirketleşme: Osmanlı Sanayii Monografi ve Yorumlar (From the Ottoman Empire to the Republic: Corporateization in Ottoman Industry Monographs and Comments), 1991.

8. Korkut Boratav, Türkiye İktisat Tarihi 1908-1985 (Economic History of Turkey 1908-1985), 1998.

9. Mustafa Bozdemir, Osmanlı’dan Cumhuriyet’e Endüstriyel Mirasımız (Our Industrial Heritage from the Ottoman Empire to the Republic), 2011.

10. Niyazi Berkes, Türkiye’de Çağdaşlaşma (Modernization in Turkey), 2002.

11. Rifat Önsoy, Tanzimat Dönemi Osmanlı Sanayii ve Sanayileşme Politikası (Tanzimat Era Ottoman Industry and Industrialization Policy), 1988.

12. Şevket Pamuk, Osmanlı’dan Cumhuriyet’e Küreselleşme, İktisat Politikaları ve Büyüme (From the Ottoman Empire to the Republic: Globalization, Economic Policies, and Growth), 2008.

13. Şevket Pamuk, Osmanlı Türkiye İktisadi Tarihi 1500-1914 (Economic History of Ottoman Turkey 1500-1914), 1999.

14. Vahdettin Engin, Osmanlı Ticaret ve Sanayi Albümü (Ottoman Trade and Industry Album), 2011.

Önceki Yazılar

-

NO MARRIAGE WITHOUT PERMISSION!24.07.2024

-

THE TRUTH OF KARBALA17.07.2024

-

CONTRIBUTIONS OF THE TURKS TO ISLAM10.07.2024

-

OUR TRADITION OF THE ENTARI (JALLABIA ) HAS YIELDED TO TIME3.07.2024

-

GALLOPING THROUGH HISTORY: THE OTTOMAN EMPIRE'S POSTAL COURIERS26.06.2024

-

SUMMER HAS COME, LET'S GO ON AN EXCURSION...19.06.2024

-

HOW DID THE TURKS LOSE THE ARAB LANDS?12.06.2024

-

IT WAS AN ART OF EXECUTIONER...5.06.2024

-

ARAB NATIONALISM AND THE TURKS29.05.2024

-

HOW DID TURKS BECOME MUSLIM?22.05.2024